Steam

Steam Plant by DGA.

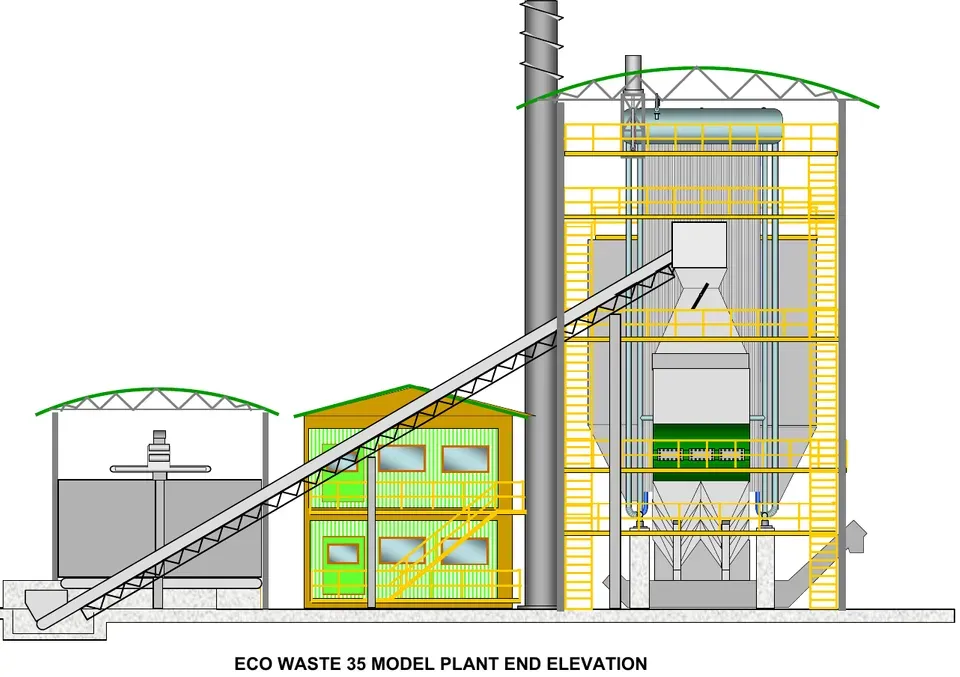

The Steam Plant uses the DGA Vee Grate, DGA or Lodge Cottrell Gas Cleaning, Triveni Steam Turbines and the DGA/ERK boiler.

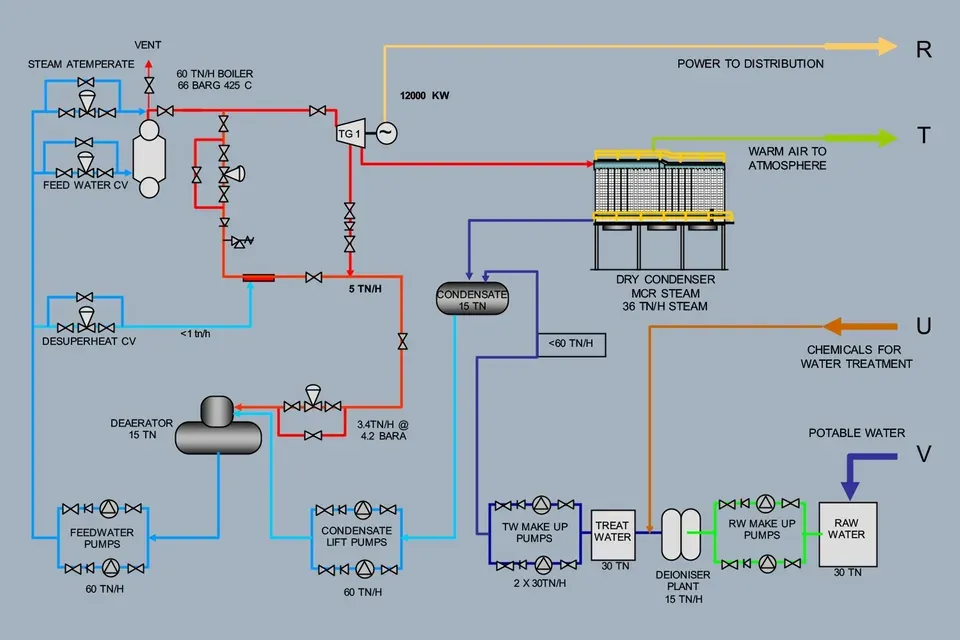

Condensing steam turbines are employed when steady and continuous power generation is the main requirement. These turbines are recommended for plants where high reliability in power generation is required or in waste-heat recovery plants where power is generated from inexpensive fuels.

While the main steam flows through the turbine and into the condenser, steam can also be bled from the turbine for feedwater heating to increase overall plant efficiency.

The customer has a choice in which company supplies the Turbine but DGA recommends that this decision be made very carefully.

DGA normally uses Triveni Turbines for quality and at a reasonable cost.

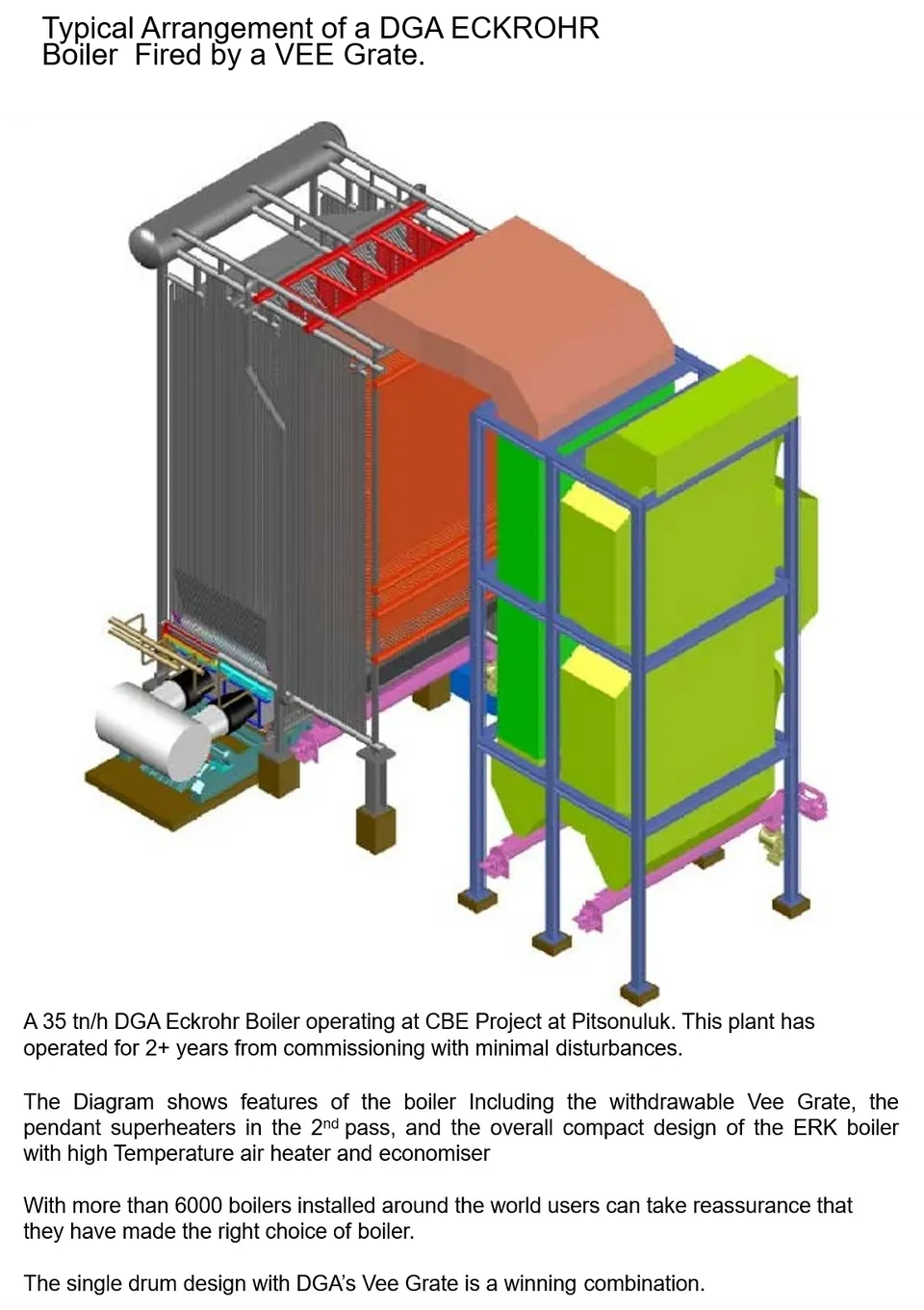

Main features of the DGA Eckrohr boiler are :

- The boiler is manufactured under license from ERK Eckrohrkessel GmbH of Berlin Germany, for many, the world’s premier boiler designer.

- The ERK license family have built in excess of 6000 boilers since ERK was formed some 60 years ago. Most boilers are installed in Europe.

- The boiler is suited to both MSW and RDF (Refuse Derived Fuel) combustion. The 3 pass design is a very versatile design and suitable for all fuels.

- The Vee Grate was designed specifically for the ERK boiler, allowing the boiler to be compact, and to use all the advantages of a staged combustion firing, i.e. high efficiency, low Nox and low CO with low excess air with a wide range of fuels. ERK designed boilers can be factory assembled, and then “knocked down” for transport to site for final erection.

- This reduces expensive site time erection.

- The ERK boiler are so favoured by boiler operators worldwide.

- The boilers are generally built to ASME code and can be completed anywhere the facilities exist to the meet this standard.

- The Single Grate range extends from 10 tn/h to 60 tn/h boilers with high pressure and temperature, can generate from 1 to 12 MWe from a suitable turbine generator.

Quick Start Up

- At start up water circulation starts very quickly as the distances from downcomers to the heated risers on the water side are consistent and short.

- The short distances mean that all water tubes reach saturation temperature quickly, so potentially dangerous thermal stresses in the boiler are avoided.

- There is no bottom drum containing large quantity of water which must be heated during start up on bi-drum designs.

- The steam drums is isolated from flue gases so thermal stress and corrosion in this area is avoided. Bidrum boilers are generally swept by the flue gases.

- The tube connections to the drum on an Eckrohr boiler are few and of large bore. The design allows for the loss of metal at each penetration leading to considerably thinner drum shells than bi-drum boilers.

- Bi-drum boilers have many small tube penetrations so it is necessary to design the drums on their ligament efficiency. This can double the metal thickness. Thin drum walls reduce thermal stress during the light up cycle.

- Even and thin metal thickness of the drum means that drum distortion during light up is minimal.

- Downcomers are large and uncooled. Steam bubbles forming at pressure fluctuations and high load change can not endanger water circulation.

Self Supporting Construction.

- Thermal expansion is from bottom to top. This is an advantage with grate firing because the expansion difference between boiler and grate is minimal. With top hung designs sealing between grate and boiler can be difficult.

Low Pressure variations at Load Changes.

- Quick Load variations are possible without significant changes of steam pressure.

- Water level in the drum remains calm compared to other boiler designs.

High Steam Purity.

- Steam separation system takes place in the drum and external to the drum in the large bore overflow pipes and steam headers. High steam purity can be achieved even with poor water quality.

Economical space requirements.

- The design using external downcomers allows heat exchangers to be located some distance from the drum allowing compact arrangements to be designed.

- Compact designs have been developed which allows completed boilers to be delivered to site in one piece.

References.

- The ERK boiler has 6000 references around the world firing all fuels with many Waste and Biomass many Fired units mainly in Europe. The reference plants have been built by other Eckrohrkessel licensees and all information and experience on these plants transfer to DGA via the ERK licence system.

- DGA/BIB/Sbang have a number of ERK boiler references which have been constructed over the past 15 years, most recently:

- The 60 tn/h boiler for APK at Hat Yai

- The 45 tn/h boiler at Natural Palm

- The 45 tn/h boiler at Clover Prae

- The 30 tn/h boiler at CBE Project Pitsonuluk

Suitable Fuels for the DGA Eckrohr Boiler.

The following Waste fuels are suitable for firing on a Vee grate in a DGA Eckrohr Boiler:

- The full range of Biomass fuels for initial start of the boiler including

- Palm Wastes, including EFB

- Rubber Wood slab and stump

- Rice Husk

- Bagasse

- Range of from Eucalypus Fuels

- Wood chip

- Fresh bark

- Bituminous Coal

The following Waste Fuels are suitable for firing on a Vee Grate in a DGA Eckrohr Boiler.

Sized raw waste with LCV > 7000 kJ/kg- Refuse Derived Fuel (RDF) from a suitable treatment system

Combustion Requirements.

The fuel must be sized in accordance with DGA Product Sheet Fuel Sizing for DGA Grates LCV constraints.

DGA will advise the ability of the DGA Eckrohr boiler to handle any waste fuel from an accurate ultimate analysis of the fuel, inclusive annual variations of Moisture Content. From this DGA calculate a real LCV which must meet the following requirements :-

- LCV must be better than 4500 kJ/kg if superheat steam required.

- The Moisture content of biomass must be lower than 55%.

The boiler will be fitted with a flue gas air heater if high air preheat is necessary due to low LCV. This can be as high as 300 C on the standard grate allowing wetter fuel to be burned.

Emission Constraints:

The emissions must meet the Emission Criteria published by the relevant Government. DGA target the EU WID limits to ensure a comfortable compliance.

Mainly relevant to Waste fired plants including RDF. If the Ultimate Analysis show that any of the following are high, then an upgraded gas scrubbing system is required.

- Sulphur and Chlorine contents.

- Heavy Metals.

- Dioxin and Furans.