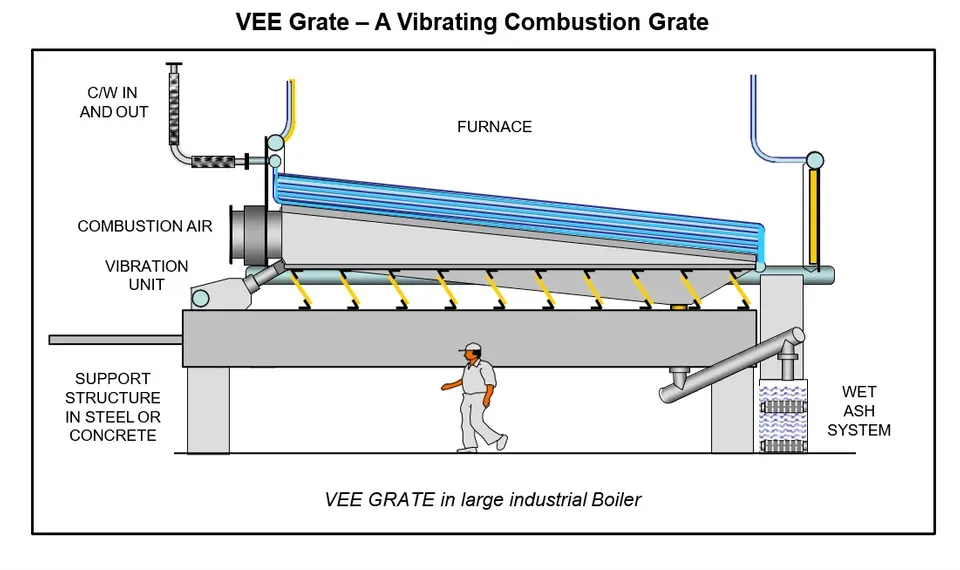

DGA Vee Grate

Main features of the DGA VEE Grate are:

- Cast Iron Grate Bars on cooled frame for good temperature resistance and low wear.

- No moving parts in the airbox so high preheat temperatures. Up to 350 C can be used.

- Water cooling by low pressure and temperature water from Deaerator.

- No fixed pipes to break. Design uses flexible hoses with isolators so can be changed with boiler on load.

- Intermittent vibration action to reduce impact on surrounding structures. High amplitude low frequency action gives good directional stability to movement.

- Low vibrating mass to reduce loads on driving gear springs and structure.

- High quality spring steel leaf springs installed outside the air box for longevity. Zone control to air flow under the grate for combustion control.

- Flexible air bellows installed outside the boiler enclosure for easy change out of fabric bellows.

- High temperature fabric bellows to isolate vibration.

- May be used for staged combustion when arranged with a secondary air system similar to BFB system.

- Grates can be arranged in multiple sections which are joined together with a fuel tight connector. This allows each section to be vibrated independently.

- In theory the furnace can be as wide as required to fire the largest furnace. When ground mounted the grate or grates can be withdrawn from the boiler.

End view of the VEE Grate shows the method of installing the grates side by side to allow them to fire any size boiler.

The design ensures that the vibrated mass is the minimum compatible with structural strength which is provided by the space frame construction. This ensures that the vibration is minimised on even the largest grates.

Elevated on a structure some vibration may be felt though the boiler when the drive is operating, but careful design of the structure and footings minimises the impact of the vibration.

Intermittent vibration, and vibration of each unit separately ensures that the effects are temporary.

The VEE Grate has been developed from earlier versions which are in regular use in SE Asia for the combustion of Biomass fuels, from palm waste to rice husk.

The increased size of the grate and the location at ground level allows grate to be easily removable for maintenance.

DGA Vibrating Combustion Grates.

Have been developed as a grate capable of firing all biomass solid fuels, from palm oil waste through wet bark and wood wastes to clean wood chip and even bituminous coal.

Fuel Spreading.

Fuel is spread through the flames already established on the grate to cause ignition of the incoming fuel. The ignited fuel lands on the grate adding to the established fuel bed, and the action of the grate moves the whole fuel bed towards the front of the grate where the ash discharge conveyor is located.

Gentle Wear.

The vibrating action of the grate moves the fuel bed gently down the grate with little wear to the grate surface. The vibrating causes the fuel to be spread to an even depth on the grate and together with the air drafting dislodges the ash particles from the live fuel. Denser ash falls as bottom ash to the ash discharge conveyor.

High Air Preheat.

Because there are no moving or rotating parts in the combustion air box high levels of air preheat are available to allow combustion of even very wet biomass fuel.

Handles sticky fuels.

The combustion deck of the grate is water cooled in order to stop fuels from sticking to the grate during combustion and also to retain the physical strength of the construction material.

Low Vibrated mass.

Attention has been given to reducing the overall vibrated mass so the grate is built around a space frame in light clad material. In order to reduce the impact of the vibration.

Good Combustion.

Combustion of solid fuel is the major part of the design of this grate so it has been designed for good distribution of combustion air, injected at optimum pressure for good air:solid mixing on the grate.

High Thermal Rating.

Up to 2 MW/m2 is available for most biomass fuels. This reduces to ~ I MW/m2 with low calorific value low reactivity coals.

High Efficiency.

The main feature of the grate is that it forms the heart of a modern high efficiency firing system, that is able to burn a variety of biomass fuels, sized for < 80 mm particles with good fuel burn out i.e. low carbon in ash, even when fired at low excess air. Standard grates are available to operate at 45% excess air and with staged air combustion this can reduce to ~ 30 % excess air.

This picture was shot through the peephole of a furnace whilst the boiler was firing at high load on Palm Empty Fruit Bunch. The stack was clear.

Ancillary Equipment that may be supplied with the Vee Grate:

- Spreader Stokers for Biomass. These are also used for waste materials such as RDF.

- Mechanical Spreaders for coal and lump biomass.

- Variable screw feeders for biomass and or solid fuel.

- Wet ash discharge conveyors.

- Vibrating sequence Control.